Voltage-Compatible Heating Elements Abroad

Understanding Voltage-Compatible Heating Elements

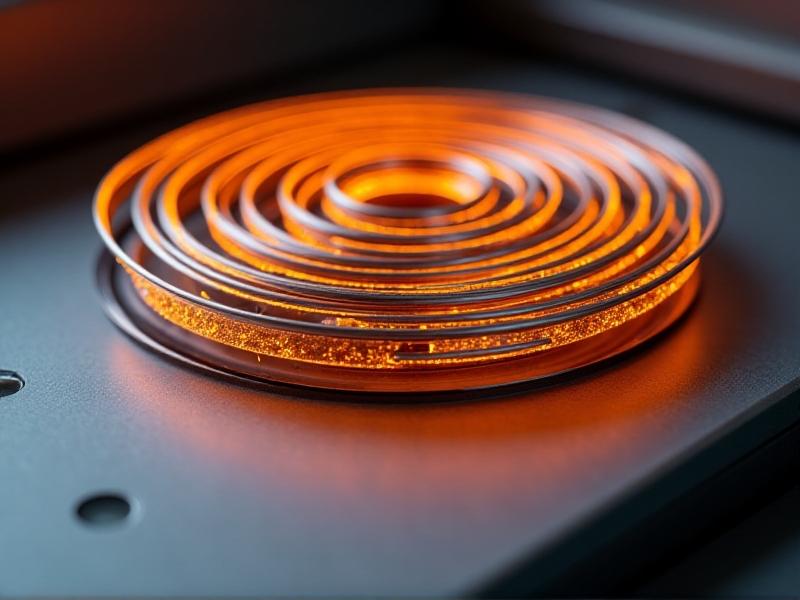

Heating elements are essential components in various appliances, from electric kettles to industrial furnaces. One critical aspect of these elements is their voltage compatibility, especially when used abroad. Different countries have varying voltage standards, and using a heating element designed for one voltage in a region with another can lead to inefficiency or even damage. Voltage-compatible heating elements are designed to function optimally across different voltage ranges, ensuring safety and performance regardless of location.

The Importance of Voltage Compatibility in Global Markets

As businesses expand globally, the need for voltage-compatible heating elements becomes increasingly significant. Manufacturers must consider the electrical standards of their target markets to avoid costly returns or reputational damage. For instance, a heating element designed for the 220-240V range in Europe may not perform well in the United States, where the standard is 110-120V. Understanding these differences and incorporating voltage compatibility into product design can enhance marketability and customer satisfaction.

Designing Voltage-Compatible Heating Elements

Designing heating elements that are compatible with multiple voltages involves careful engineering. Engineers must consider factors such as resistance, wattage, and material properties to ensure the element can handle different electrical inputs without compromising performance. Advanced materials like nichrome and Kanthal are often used due to their excellent thermal and electrical properties. Additionally, incorporating safety features like thermal fuses can prevent overheating and ensure longevity.

Applications of Voltage-Compatible Heating Elements

Voltage-compatible heating elements find applications in a wide range of industries, from consumer electronics to industrial machinery. In the consumer sector, they are used in appliances like hair dryers, coffee makers, and space heaters. In industrial settings, they are crucial in processes like plastic molding, food processing, and chemical manufacturing. The versatility of these elements makes them indispensable in both everyday life and specialized industrial applications.

Challenges in Manufacturing Voltage-Compatible Heating Elements

Manufacturing voltage-compatible heating elements presents several challenges. One of the primary issues is ensuring consistent quality across different voltage ranges. Variations in voltage can affect the element's performance, leading to potential failures. Additionally, sourcing materials that can withstand different electrical inputs without degrading is crucial. Manufacturers must also navigate regulatory requirements in various countries, which can add complexity to the production process.

Future Trends in Voltage-Compatible Heating Technology

The future of voltage-compatible heating elements is promising, with advancements in materials science and electrical engineering driving innovation. Smart heating elements that can automatically adjust to different voltages are on the horizon, offering even greater convenience and efficiency. Additionally, the integration of IoT technology could enable remote monitoring and control, enhancing safety and performance. As the demand for global compatibility grows, these trends will shape the next generation of heating elements.

Selecting the Right Voltage-Compatible Heating Element

Choosing the right voltage-compatible heating element requires careful consideration of several factors. These include the intended application, the voltage range of the target market, and the specific requirements of the appliance or machinery. Consulting with experts and reviewing product specifications can help ensure the selected element meets all necessary criteria. Additionally, considering factors like energy efficiency and durability can lead to better long-term performance and cost savings.

Maintenance and Safety Tips for Voltage-Compatible Heating Elements

Proper maintenance and safety practices are essential for the longevity and safe operation of voltage-compatible heating elements. Regular inspections can help identify wear and tear before it leads to failure. Cleaning the elements to remove any buildup of debris or contaminants can also improve performance. Safety measures, such as using circuit breakers and ensuring proper insulation, can prevent electrical hazards. Following manufacturer guidelines and staying informed about best practices can help users get the most out of their heating elements.

Environmental Impact of Voltage-Compatible Heating Elements

The environmental impact of heating elements is an important consideration in today's eco-conscious world. Voltage-compatible heating elements that are energy-efficient can reduce electricity consumption and lower carbon footprints. Additionally, using sustainable materials and manufacturing processes can further minimize environmental impact. As regulations and consumer preferences shift towards greener products, manufacturers are increasingly focusing on developing eco-friendly heating solutions.