The Science Behind Japanese Chisel Edge Retention

The Craftsmanship of Japanese Chisels

Japanese chisels, known as "Nomi," are revered worldwide for their exceptional edge retention and precision. The secret lies in their meticulous craftsmanship, which combines centuries-old techniques with modern metallurgical advancements. Unlike Western chisels, Japanese chisels are often made from laminated steel, featuring a hard outer layer and a softer inner core. This dual-layered construction provides both durability and flexibility, ensuring the blade remains sharp even under rigorous use.

The forging process itself is a testament to the dedication of Japanese blacksmiths. Each chisel is hand-forged, with the steel folded multiple times to remove impurities and create a uniform grain structure. This labor-intensive process not only enhances the blade's strength but also contributes to its ability to retain a sharp edge. The result is a tool that is both a work of art and a functional masterpiece, capable of withstanding the demands of professional woodworking.

The Role of Steel Composition in Edge Retention

The steel used in Japanese chisels plays a crucial role in their edge retention. Typically, these chisels are made from high-carbon steel, which is known for its hardness and ability to hold a sharp edge. However, the exact composition of the steel can vary depending on the intended use of the chisel. For example, chisels designed for fine detail work may use a higher carbon content, while those intended for heavier tasks might incorporate additional alloys for added toughness.

One of the key factors that set Japanese chisels apart is the use of laminated steel. This technique involves bonding a hard, high-carbon steel edge to a softer, more flexible steel body. The hard edge provides the sharpness and durability needed for cutting, while the softer core absorbs shocks and prevents the blade from cracking or chipping. This combination of materials ensures that the chisel remains sharp even after prolonged use, making it a favorite among professional woodworkers.

Heat Treatment and Its Impact on Durability

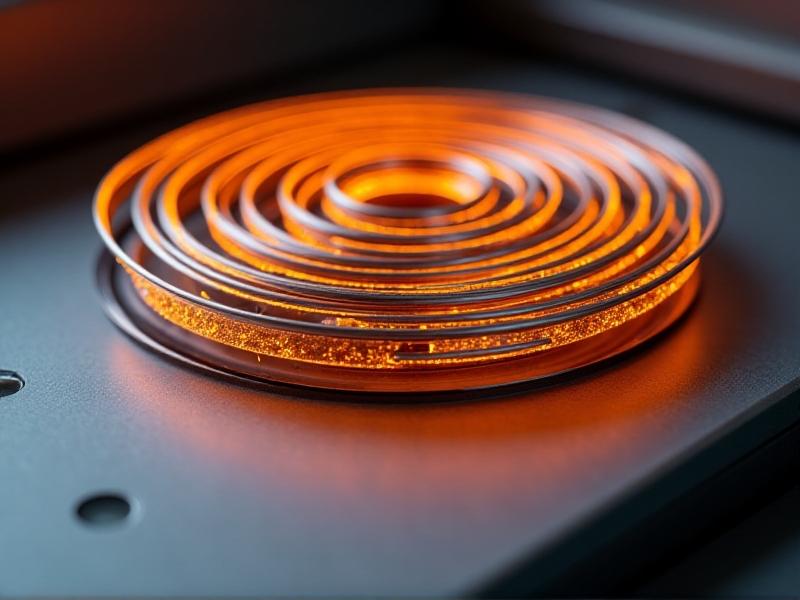

Heat treatment is another critical factor in the edge retention of Japanese chisels. After the blade is forged, it undergoes a series of heat treatments to enhance its hardness and toughness. The process typically involves heating the blade to a high temperature and then rapidly cooling it, a technique known as quenching. This rapid cooling locks the steel's molecular structure in place, creating a hard, durable edge.

However, the heat treatment process doesn't end with quenching. The blade is then tempered, or reheated to a lower temperature, to reduce brittleness and improve toughness. This careful balance between hardness and toughness is what gives Japanese chisels their legendary edge retention. The result is a blade that can withstand the rigors of heavy use without losing its sharpness, making it an indispensable tool for any serious woodworker.

The Importance of Blade Geometry

Blade geometry is another essential aspect of Japanese chisel design that contributes to their edge retention. Unlike Western chisels, which often have a single bevel, Japanese chisels typically feature a double bevel. This design allows for a sharper edge and more precise cuts, making it ideal for detailed woodworking tasks. The angle of the bevel is carefully calculated to balance sharpness and durability, ensuring that the blade remains effective even under heavy use.

In addition to the bevel angle, the overall shape of the blade also plays a role in edge retention. Japanese chisels often have a slightly curved edge, which helps to distribute force evenly across the blade. This design reduces the risk of chipping or cracking, even when the chisel is used for heavy-duty tasks. The result is a tool that is both sharp and durable, capable of handling a wide range of woodworking challenges.

Sharpening Techniques for Optimal Edge Retention

Proper sharpening is essential for maintaining the edge retention of Japanese chisels. The process typically involves using a series of sharpening stones, starting with a coarse grit to remove any nicks or imperfections and gradually moving to finer grits to polish the edge. The goal is to create a razor-sharp edge that is both durable and precise.

One of the key techniques used in sharpening Japanese chisels is the use of a micro-bevel. This involves creating a very small secondary bevel at the very edge of the blade, which helps to enhance sharpness and durability. The micro-bevel is typically created using the finest grit stone, and it is this final touch that gives Japanese chisels their legendary edge retention. With proper care and maintenance, a Japanese chisel can remain sharp for years, making it a valuable investment for any woodworker.

The Cultural Significance of Japanese Chisels

Japanese chisels are more than just tools; they are a reflection of Japan's rich cultural heritage and dedication to craftsmanship. The art of chisel-making has been passed down through generations, with each blacksmith adding their own unique touch to the process. This tradition of excellence is evident in every aspect of the chisel, from the quality of the steel to the precision of the blade geometry.

In Japan, the chisel is not just a tool but a symbol of the artisan's skill and dedication. The process of making a chisel is seen as a form of meditation, with each step performed with care and attention to detail. This cultural significance is what sets Japanese chisels apart from their Western counterparts, making them a favorite among woodworkers who value both performance and tradition. Whether you're a professional woodworker or a hobbyist, a Japanese chisel is a tool that embodies the best of both worlds.

Comparing Japanese Chisels to Western Chisels

When it comes to edge retention, Japanese chisels often outperform their Western counterparts. The key difference lies in the materials and techniques used in their construction. While Western chisels are typically made from a single piece of steel, Japanese chisels use laminated steel, which combines the hardness of high-carbon steel with the flexibility of softer steel. This dual-layered construction provides both durability and sharpness, ensuring that the blade remains effective even under heavy use.

Another factor that sets Japanese chisels apart is their blade geometry. While Western chisels typically have a single bevel, Japanese chisels feature a double bevel, which allows for a sharper edge and more precise cuts. Additionally, the slightly curved edge of Japanese chisels helps to distribute force evenly, reducing the risk of chipping or cracking. These design features, combined with the superior materials and craftsmanship, make Japanese chisels a top choice for woodworkers who demand the best in edge retention and performance.

Maintaining Your Japanese Chisel for Longevity

Proper maintenance is essential for ensuring the longevity and edge retention of your Japanese chisel. This includes regular sharpening, as well as proper storage and care. After each use, it's important to clean the blade and remove any wood shavings or debris. This helps to prevent rust and keeps the blade in optimal condition.

When it comes to sharpening, it's important to use the right techniques and tools. As mentioned earlier, Japanese chisels benefit from the use of a micro-bevel, which enhances sharpness and durability. Additionally, it's important to use high-quality sharpening stones and to follow the correct sequence of grits. With proper care and maintenance, a Japanese chisel can remain sharp and effective for many years, making it a valuable investment for any woodworker.

The Future of Japanese Chisel Making

As technology advances, the art of Japanese chisel making continues to evolve. While traditional techniques remain at the heart of the process, modern innovations are helping to enhance the quality and performance of these tools. For example, some blacksmiths are now using computer-controlled heat treatment processes to achieve more precise and consistent results. Additionally, new materials and alloys are being explored to further improve edge retention and durability.

Despite these advancements, the core principles of Japanese chisel making remain unchanged. The focus is still on quality, craftsmanship, and attention to detail. This commitment to excellence is what ensures that Japanese chisels will continue to be a top choice for woodworkers around the world. Whether you're a professional or a hobbyist, a Japanese chisel is a tool that embodies the best of both tradition and innovation.