Selecting the Right Grit for Ice Chisel Sharpening

Understanding the Importance of Grit in Ice Chisel Sharpening

Sharpening an ice chisel is not just about maintaining its edge; it’s about ensuring safety and efficiency during use. The grit of the sharpening tool plays a pivotal role in this process. Grit refers to the size of the abrasive particles on the sharpening stone or tool, and it determines how much material is removed from the chisel’s edge. Selecting the right grit is crucial because it directly impacts the sharpness, durability, and performance of the chisel. Too coarse a grit can damage the blade, while too fine a grit may not be effective for heavy-duty tasks like ice chiseling. Understanding the science behind grit selection is the first step toward mastering the art of sharpening.

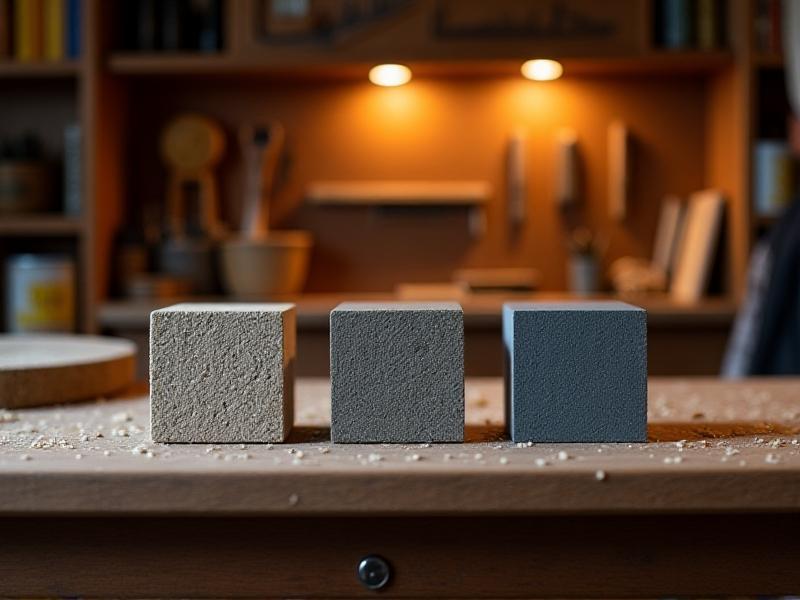

Types of Grit and Their Applications

Grit is categorized into three main types: coarse, medium, and fine. Coarse grit, typically ranging from 80 to 200, is used for reshaping or repairing damaged edges. Medium grit, between 300 and 800, is ideal for regular maintenance and sharpening. Fine grit, above 1000, is used for polishing and refining the edge to a razor-sharp finish. For ice chisels, a combination of medium and fine grit is often recommended. Medium grit removes nicks and imperfections, while fine grit ensures a smooth, durable edge capable of cutting through ice with minimal effort. Knowing which grit to use at each stage of sharpening is essential for achieving optimal results.

Factors to Consider When Selecting Grit

Several factors influence the choice of grit for sharpening an ice chisel. The condition of the blade is the primary consideration. A damaged or dull blade requires coarse grit to reshape the edge, while a well-maintained blade may only need fine grit for polishing. The type of ice being chiseled also matters. Hard, compact ice demands a sharper edge, which can be achieved with finer grit. Additionally, the user’s skill level and the frequency of use play a role. Beginners may prefer medium grit for its versatility, while experienced users might opt for a combination of grits for precision. Considering these factors ensures that the chosen grit aligns with the specific needs of the task.

Step-by-Step Guide to Sharpening with the Right Grit

Sharpening an ice chisel with the appropriate grit involves a systematic approach. Start by inspecting the blade to determine its condition. If the edge is damaged, begin with coarse grit to reshape it. Hold the chisel at a consistent angle, typically between 20 and 30 degrees, and move it across the stone in smooth, even strokes. Once the edge is restored, switch to medium grit to refine it further. Finally, use fine grit to polish the edge and achieve a razor-sharp finish. Throughout the process, ensure that the blade is evenly sharpened and free of burrs. Proper technique, combined with the right grit, guarantees a sharp and durable ice chisel.

Common Mistakes to Avoid When Choosing Grit

Selecting the wrong grit is a common mistake that can compromise the effectiveness of an ice chisel. Using coarse grit on a blade that only needs fine grit can remove too much material, shortening the tool’s lifespan. Conversely, using fine grit on a damaged blade may not adequately restore the edge. Another mistake is neglecting to progress through grits sequentially. Skipping from coarse to fine grit without using medium grit can leave the edge uneven and less effective. Additionally, failing to maintain a consistent angle during sharpening can result in an uneven edge. Avoiding these mistakes ensures that the chisel remains sharp and functional.

Maintaining Your Ice Chisel After Sharpening

Proper maintenance is essential to preserve the sharpness and longevity of an ice chisel. After sharpening, clean the blade to remove any metal shavings or debris. Store the chisel in a dry place to prevent rust, and consider applying a light coat of oil for added protection. Regularly inspect the edge for signs of wear or damage, and touch it up with fine grit as needed. Avoid using the chisel on surfaces other than ice, as this can dull the edge prematurely. By following these maintenance tips, you can ensure that your ice chisel remains in top condition for years to come.

Expert Tips for Selecting and Using Grit

Experienced sharpeners often share valuable tips for selecting and using grit effectively. One tip is to invest in high-quality sharpening stones, as they provide consistent results and last longer. Another is to use a honing guide to maintain a consistent angle, especially for beginners. For tough ice conditions, consider using a slightly coarser grit to ensure the edge remains sharp throughout the task. Additionally, practice on an old or inexpensive chisel before working on your primary tool. These expert tips can help you refine your sharpening skills and achieve professional-level results.

The Role of Grit in Enhancing Safety and Efficiency

Selecting the right grit not only improves the performance of an ice chisel but also enhances safety and efficiency. A properly sharpened chisel requires less force to cut through ice, reducing the risk of injury from slips or overexertion. It also ensures cleaner, more precise cuts, which is especially important for tasks like ice fishing or creating ice sculptures. By choosing the appropriate grit and sharpening the chisel correctly, you can work more effectively and safely in icy conditions. This makes grit selection an essential aspect of ice chisel maintenance.

Conclusion: Mastering the Art of Grit Selection

Selecting the right grit for ice chisel sharpening is both a science and an art. It requires an understanding of the different types of grit, the factors that influence their selection, and the techniques for using them effectively. By following the guidelines and tips outlined in this article, you can ensure that your ice chisel remains sharp, durable, and ready for any icy challenge. Whether you’re a beginner or an experienced user, mastering grit selection is a skill that will enhance your performance and safety in cold weather conditions.