Food-Grade Dye Injection Systems for Ice Blocks

Introduction to Food-Grade Dye Injection Systems for Ice Blocks

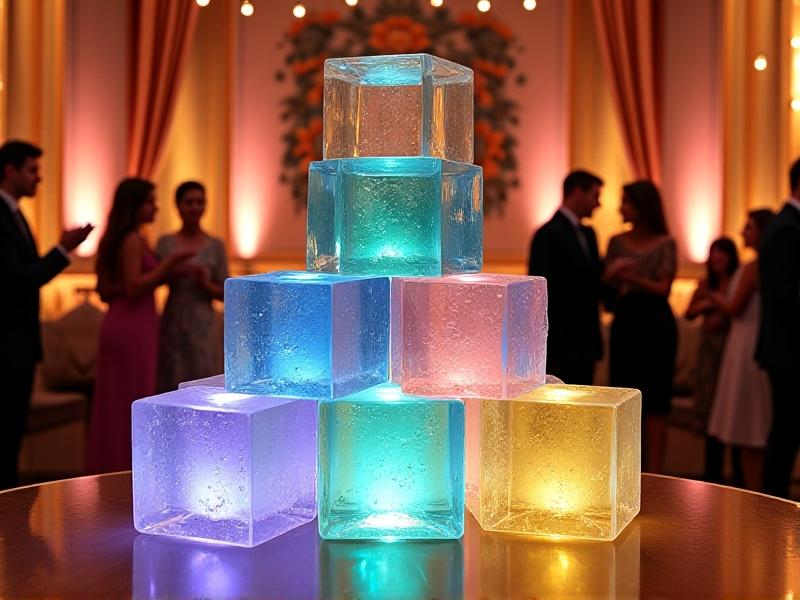

In the world of food presentation and preservation, the use of colored ice blocks has become increasingly popular. Whether for enhancing the visual appeal of beverages, creating themed events, or ensuring food safety, food-grade dye injection systems play a crucial role. These systems are designed to infuse ice blocks with vibrant, safe, and consistent colors, meeting the stringent standards required for food contact. This article delves into the intricacies of food-grade dye injection systems, exploring their benefits, components, applications, and future trends.

The Science Behind Food-Grade Dyes

Food-grade dyes are specially formulated to be safe for human consumption. Unlike industrial dyes, they undergo rigorous testing to ensure they are free from harmful chemicals and contaminants. These dyes are typically water-soluble, allowing them to mix seamlessly with water during the ice-making process. The science behind these dyes involves understanding their molecular structure, stability at low temperatures, and interaction with water molecules. This ensures that the color remains vibrant and consistent throughout the ice block, even as it melts.

Components of a Dye Injection System

A typical food-grade dye injection system consists of several key components: a dye reservoir, injection nozzles, a control panel, and a mixing chamber. The dye reservoir stores the concentrated dye, which is then pumped through the injection nozzles into the water before it freezes. The control panel allows operators to adjust the dye concentration, injection rate, and other parameters to achieve the desired color intensity. The mixing chamber ensures that the dye is evenly distributed throughout the water, resulting in a uniformly colored ice block.

Applications of Colored Ice Blocks

Colored ice blocks have a wide range of applications across various industries. In the food and beverage industry, they are used to enhance the visual appeal of cocktails, smoothies, and other drinks. In the event planning industry, they are used to create themed decorations and centerpieces. In the medical and pharmaceutical industries, colored ice blocks can be used to mark and identify specific samples or medications. The versatility of colored ice blocks makes them a valuable tool in many different settings.

Benefits of Using Food-Grade Dye Injection Systems

There are several benefits to using food-grade dye injection systems for ice blocks. First and foremost, they ensure that the dyes used are safe for consumption, meeting all regulatory requirements. They also provide precise control over the color intensity and distribution, resulting in consistent and high-quality ice blocks. Additionally, these systems are designed to be easy to use and maintain, making them a practical choice for both small businesses and large-scale operations. The ability to customize the color of ice blocks also opens up new creative possibilities for food and beverage presentation.

Challenges and Considerations

While food-grade dye injection systems offer many benefits, there are also some challenges and considerations to keep in mind. One of the main challenges is ensuring that the dye is evenly distributed throughout the ice block, which requires precise control over the injection process. Another consideration is the potential for dye residue to accumulate in the system over time, which can affect the color consistency and require regular cleaning and maintenance. Additionally, operators must be trained to use the system correctly to avoid over-dyeing or under-dyeing the ice blocks.

Future Trends in Dye Injection Technology

As technology continues to advance, we can expect to see several trends in the development of food-grade dye injection systems. One trend is the integration of smart technology, allowing for remote monitoring and control of the system through mobile apps or cloud-based platforms. Another trend is the development of more sustainable and eco-friendly dyes, reducing the environmental impact of colored ice production. Additionally, we may see the introduction of new dye formulations that offer enhanced stability and vibrancy, further improving the quality of colored ice blocks.

Case Studies: Successful Implementations

Several businesses have successfully implemented food-grade dye injection systems to enhance their products and services. For example, a high-end cocktail bar in New York City uses colored ice blocks to create visually stunning drinks that have become a signature feature of their menu. A catering company in Los Angeles uses colored ice blocks to create themed decorations for weddings and corporate events, adding a unique touch to their services. These case studies demonstrate the potential of food-grade dye injection systems to transform businesses and create memorable experiences for customers.

How to Choose the Right Dye Injection System

Choosing the right food-grade dye injection system depends on several factors, including the scale of production, the desired color intensity, and the specific application. For small businesses, a compact and easy-to-use system may be sufficient, while large-scale operations may require a more advanced system with greater capacity and control. It's also important to consider the maintenance requirements and the availability of technical support when selecting a system. By carefully evaluating these factors, businesses can find a dye injection system that meets their needs and enhances their products.

Maintenance and Care of Dye Injection Systems

Proper maintenance and care are essential to ensure the longevity and performance of food-grade dye injection systems. Regular cleaning of the dye reservoir, injection nozzles, and mixing chamber is necessary to prevent dye residue buildup and maintain color consistency. It's also important to inspect the system for any signs of wear or damage and replace any worn-out parts as needed. By following the manufacturer's maintenance guidelines and scheduling routine inspections, businesses can keep their dye injection systems in optimal condition and avoid costly repairs or downtime.

Conclusion: The Future of Colored Ice Blocks

The use of food-grade dye injection systems for ice blocks is a testament to the importance of innovation in the food and beverage industry. These systems not only enhance the visual appeal of products but also ensure safety and consistency. As technology continues to evolve, we can expect to see even more advanced and sustainable solutions that push the boundaries of what is possible with colored ice blocks. Whether for creating stunning cocktails, themed decorations, or medical applications, food-grade dye injection systems are set to play a pivotal role in the future of food presentation and preservation.